TPV AUTOMOTIVE awarded one gold and two bronze for innovation by Chamber of Commerce and Industry of Slovenia

26.9.2022

After having received two gold and five bronze awards for innovation at regional level, TPV AUTOMOTIVE was awarded with national gold and two bronze by Chamber of Commerce and Industry of Slovenia.

On 20 September, 2022, Chamber of Commerce and Industry of Slovenia awarded the most innovative individuals, companies and other institutions at national level. The awards represent the highest national recognition of innovative achievements for Slovenian companies and promote innovation in Slovenia.

Three of total 45 innovations that qualified to the national level are the fruit of TPV AUTOMOTIVE. These innovations were ranked highest already at regional level and did not disappoint at national level as they received one gold and two bronze.

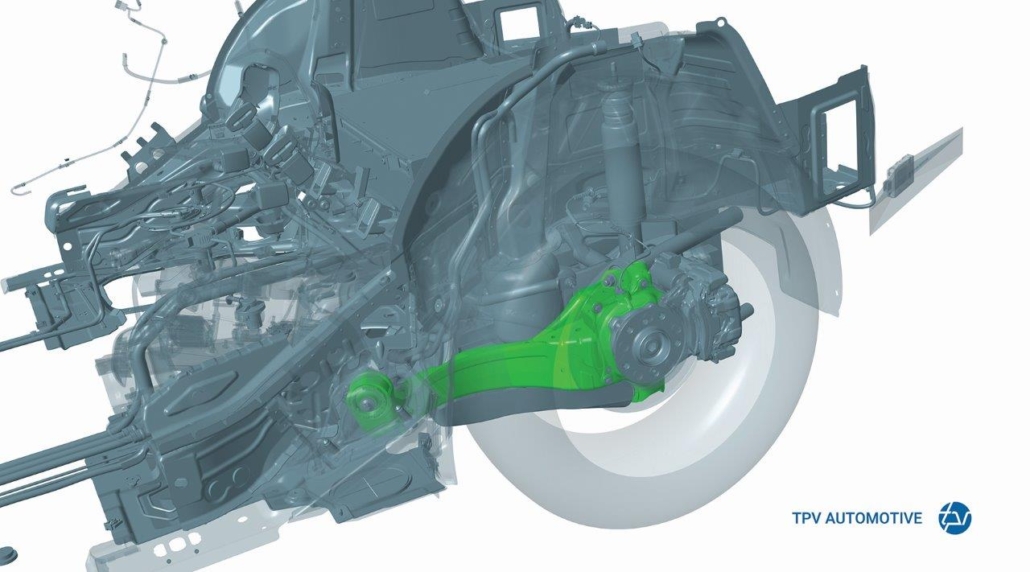

Gold was awarded for Development of a light thin-walled trailing arm subjected to high dynamic loads for the entire BMW platform. The innovation solves the challenges of making a very complex and dynamically loaded chassis safety component in terms of geometry, stiffness, strength and lightweight design with limited tolerances, high corrosion demands and minimal material consumption in large-scale production. The product is universal to BMW platform ranging from conventional to hybrid and fully electric vehicles and it will be mounted in over 40% of new BMW vehicles. The innovation is considered a disruptive innovation on a global scale. TPV AUTOMOTIVE d.o.o. brought this product to life after 5 years of development from initial design to large-scale production, together with the help of over twenty Slovenian and foreign institutions and partners.

Innovators: Milibor Bjelošević, Uroš Brinc, Tomaž Habinc, Janez Hočevar, Marko Malnarič, mag. Vili Malnarič, mag. Rajko Marinčič, Miran Penič, Boštjan Piletič, Miran Podpečan, Patricia Šašek, Krunoslav Šimrak, Jurij Švegelj, Davor Tramte, Dejan Zajec.

Bronze was awarded for:

- Development of thrust rod for improvement of driving dynamics: At development of thrust rod, we used our innovative solutions to prolong the lifetime of the component and improve driving dynamics. We reduced the possibility of failure and reduced mass and contributed to lower carbon footprint. With the new design we solved the problem of optimal outflow of surface protection, eliminated the possibility of production errors and enabled lower cost of the production process where we improved the safety and well-being of employees. We followed the guidelines of environmental impact reduction and successfully changed the surface protection to more eco-friendly solution.

Innovators: Jurij Kuretič, Marko Malnarič, Klemen Novak, Miran Podpečan, Patricia Šašek, Dejan Zajec.

- Innovative production cutting line with integrated unit for machining of »fastening module M5«: We developed a new innovative compact machining high-series process by combining two phases of M5 threaded module production for the customer Volvo. The advantage of the newly developed cutting line with integrated machining unit is that it combines the functionality of two classic production processes, it has automated interphase manipulation between individual work units, it takes up less work space, consumes less energy and thus significantly contributes to more efficient use of energy resources.

Innovators: Matija Požgaj, Boštjan Piletič, Matej Žerjav.