TPV AUTOMOTIVE received 10 awards for innovation

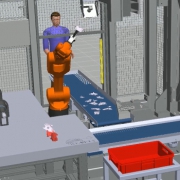

On June 13th and 14th, regional selections for the best innovations were held at Rajhenburg Castle in Brestanica and Otočec, organized by the Posavje Chamber of Commerce, Krško, and the Chamber of Commerce of Dolenjska and Bela krajina. TPV AUTOMOTIVE received two gold and eight silver awards…